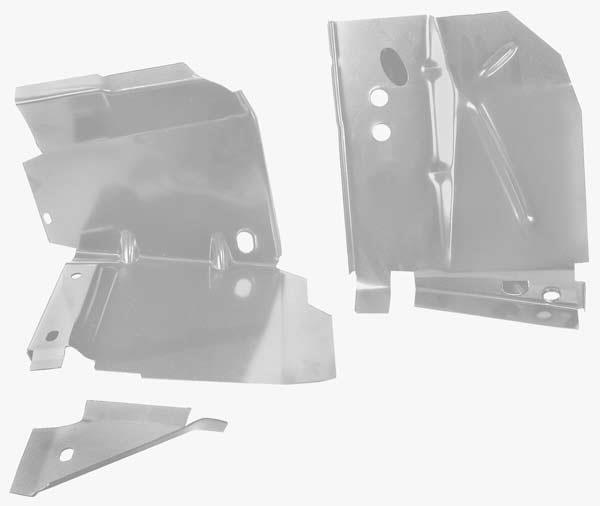

Once this is done, preheat the nozzle to 280 ☌ from LCD Menu - Settings - Temperature - Nozzle. All parts are cut, welded, and assembled in house Made in Michigan. Team Z now offers torque box reinforcement kits to replace your old worn out or tore up torque boxes on your 1979-2004 Mustang. Our kits offer multiple holes to adjust your suspension geometry, and is tied in to the frame for extra support. Step 3 alternative: if you could not follow step 3 due to firmware version up to 3.11.0 being installed, gain better access to the nozzle by moving the extruder (Z-axis) as high as possible: go to LCD Menu - Settings - Move Axis - Move Z. Our Price: 336.00 Team Z offers a lower torque box reinforcement kit to replace your old worn out or tore up torque boxes on your 1978-1987 G Body. With 10 hole adjustments and our compact modular welded design gives you the ability to create that extra tire clearance for those using Mini Tubs. Once the nozzle is at 280 ☌, the printer screen will display the following message: " Hotend at 280C! Nozzle changed and tightened to specs?".Team Z 79-04 Mustang WELDED Lower Torque Box Replacement Kit.Heating the nozzle is essential for this process. In the meantime, the printer will automatically heat the nozzle to 280 ☌. Click the LCD encoder: the printer will auto-home, and subsequently move the Z axis to the topmost position, and the X axis to the center.The printer will display a message with a link to this guide. Team Z offers a torque box reinforcement kit to replace your old worn out or tore up torque boxes on your 1979-2004 Mustang.video you can see my Merillat Racing torque boxes and Team Z Motorsports anti roll bar installed. Navigate to LCD Menu - Settings - HW Setup - Nozzle Change. In this Mustang engine swap we replace the factory 4.Optionally, perform a Cold pull (MK3S/MK2.5S). AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING. After opening the inverter, wait until the component parts have cooled down. Unload the filament, if it is loaded, from LCD Menu - Unload Filament. Connecting the AC Power Cable to the Multicluster-Box 12.Unscrew the two screws on the print fan and the single screw securing the fan shroud.Maxxim Motorsports offers service and parts. Follow this procedure exactly! Omitting steps can cause leaking and extrusion issues outlined at the end of this article. Let us take care of your ATV Service and Repair needs at RV Lifestyles.

0 kommentar(er)

0 kommentar(er)